Cattle

Cost-effective manure cleaning at farm level or biogas plant. Extensive land areas no longer required for animal production.

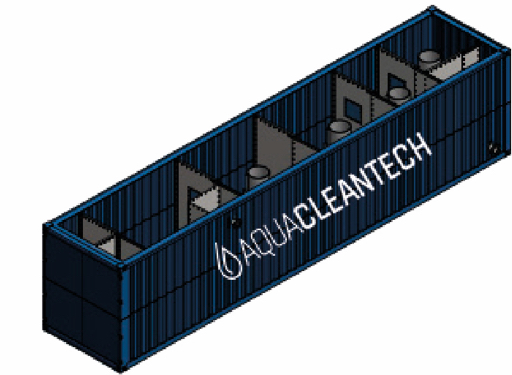

Container solutions placed on a farm to clean up to 15,000 tons manure per year or more

3-6 € in operational cost per tons manure treated

0.8-1.5 € in operation cost per kg N cleaned

Fiberfraction from separation for biogas, combustion and fertilization

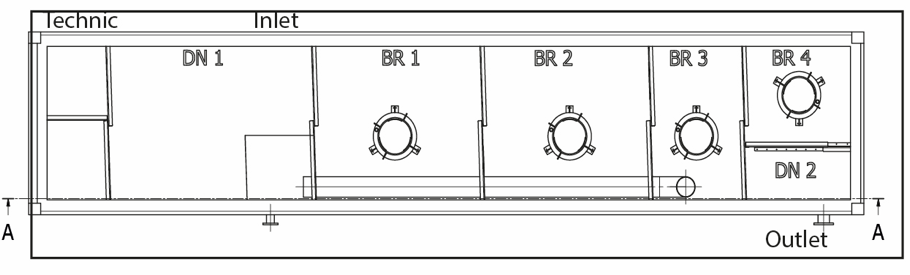

| Process step | Type | Description |

|---|---|---|

| 1 Separation | Mechanical Pre-Treatment | First separation of solids and liquid fraction |

| 2 Biological DN1 | Pre-Denitrification | Nitrate (NO3) to N2 (gas) + COD removal |

| 3 Biological BR1 | Aerobic Nitrification 1 | COD removal + ammonium (NH4) Nitrate conversion |

| 4 Biological BR2 | Aerobic Nitrification 2 | COD removal + ammonium Nitrate conversion |

| 5 Biological BR3 | Aerobic Nitrification 3 | Ammonium Nitrate conversion. Recirculating flow to Pre-Denitrification |

| 6 Biological BR4 | Aerobic Nitrification 4 | Ammonium Nitrate, Final Polishing |

| 7 Biological DN2 | Post-Denitrification | Final Nitrate polishing to free N2 gas |

| 8 Filtration | Mechanical Post-Treatment | Final polishing for TSS, COD and PO4 |

Manure cleaning for Pigs and Cattle

- Increased earnings by increasing farm capacity without expansion of farm land.

- Cost saving for disposal/export of manure by up to 70% of existing costs by reducing nutrient load in manure for spreading on available land – customized solutions.

- Fast payback of investment with payback period of 2-4 years.

- Enviromental protection by discharge of environmentally neutral N2 to the atmosphere. No agriculture land required by reducing total-N to < 150 mg/l for discharge to sewerage treatment plants or to < 10 mg/l for discharge into the natural recipient.

- P-accumulation for re-cycling by mechanical filtration, biological accumulation and/or chemical precipitation – customized solutions.

- Reduced smell due to turnover of volatile organic and inorganic gasses in closed reactors. Compact solutions with small plant footprints by container solutions form 45 to 135 m2 for 5,000-20,000 tons manure per year. Containers delivered non-insulated for installation inside insulated buildings or insulated for outdoor installation.

- Proven technology by patented biological waste water treatment technology, based on self-cleaning moving bed bio-reactor technology.

- Short delivery time from 3 months for container solutions to 6 months for industrial solutions.